В Pit Crushing Semi Mobile

Semi-mobile in-pit crushing and conveying vs. truck-shovel

Optimum location and relocation plan of semi-mobile in-pit crushing and conveying systems in open-pit mines by transportation problem International Journal of Mining, Reclamation and

获取价格

Evaluating the semi-mobile in-pit crusher option through a two

2024/8/1 To assess the semi-mobile in-pit crusher option using the proposed method, three scenarios were explored, each with distinct features: 1) no IPCC, 2) ore IPCC, and 3) ore and

获取价格

Determination of semi-mobile in-pit crushing and conveying

AvailabilityTotal Calendar TimePSDTUtilisationPerformanceModel AlgorithmAvailability is the overall number of hours that equipment is available and fit for work with a specific given period. Mathematically, availability is calculated as illustrated in Eq. 5 (Mohammadi et al. 2015): where AT is available time, TT total time, BDT breakdown time and PSDTplanned shutdown time.在link.springer上Dickson Wachira, Joseph Githiria, Moshood Onifade, Dalmus Mauti

Determination of semi-mobile in-pit crushing and conveying

Performance . Semi-mobile in-pit crushing and conveying (SMIPCC) . Utilisation Introduction In-pit crushing and conveying (IPCC) is a material handling system with a feed system, crusher,

获取价格

crushing and conveying systems - ThyssenKrupp

pit design and material characteristics • thyssenkrupp installed IPCC systems with capacities exceeding 14,000 t/h 1 2 4 1 Semi-mobile crushing plant with apron feeder and discharge

获取价格

Hierarchical Mine Planning for a Semi-Mobile In-Pit Crushing

Keywords: Semi-Mobile In-Pit Crushing and Conveying system, discrete-event simulation, open-pit mining, production scheduling, strategic and tactical planning 1 Introduction Globally,

获取价格

Ultimate pit limit determination for semi mobile in-pit crushing

Semi-Mobile In-Pit Crushing and Conveying (SMIPCC) systems are similar to fixed systems in that the crushing unit remains in one location for a period of time, with a conventional truck

获取价格

Evaluating the Semi-Mobile In-Pit Crusher Option Through a Two

2024/1/1 Identifying optimal placements for in-pit crusher throughout the mine-life establishes new series of constraints for mine planning. In this paper, a two-step mathematical

获取价格

Ultimate pit limit determination for semi mobile in-pit crushing

2019/7/23 The differences and requirements of pit design between truck haulage and semi mobile in-pit crushing and conveying systems are then highlighted. A method of including the

获取价格

Optimum location and relocation plan of semi-mobile in-pit

2018/2/20 In-pit crushing and conveying (IPCC) systems have attracted more interest among miners as an alternative to the conventional truck-shovel transportation system. The

获取价格

Determination of semi-mobile in-pit crushing and conveying

Performance . Semi-mobile in-pit crushing and conveying (SMIPCC) . Utilisation Introduction In-pit crushing and conveying (IPCC) is a material handling system with a feed system, crusher,

获取价格

A Framework for Open-Pit Mine Production

2021/4/13 In-pit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truck-and-shovel systems. However, the implementation of the

获取价格

Semi-mobile IPCC concept from Sandvik Mining Systems

观看视频4:232013/2/4 This animation demonstrates a new concept for an In-Pit Crushing Conveying (IPCC) system consisting of a semi-mobile crushing station PX100, 4 conveyors in...

获取价格

Semi-Mobile Crushing Station - YouTube

3D Animation for the client - Co. A/SThe new Semi-Mobile Crushing Station with Top Service (TS) Gyratory Crusher is ideal for in-pit crushing and ...

获取价格

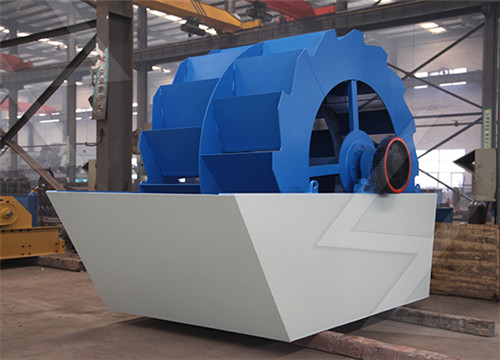

Mobile / Semi Mobile Plants – LT Construction

LT offers a range of mobile semi-mobile crushing plants. TRACK MOUNTED MOBILE PLANT. LT Track Mounted Mobile Crusher delivers the competitive advantage of mobility for applications across industry. ... It is modular in

获取价格

in-pit crushing and conveing system (IPCC) PPT

2021/2/26 4. 2. Definition of in-pit crushing and conveying (IPCC) system A continuous processing system that includes the shovel, crusher, spreader and all appropriate conveyors that reduces rock of mine (ROM) to a conveyable size.

获取价格

A Framework for Open-Pit Mine Production Scheduling under

Semi-Mobile In-Pit Crushing and Conveying Systems with the High-Angle Conveyor Dingbang Liu * and Yashar Pourrahimian Citation: Liu, D.; Pourrahimian, Y. A Framework for Open-Pit Mine

获取价格

Semi Mobile Crushers - SolidsWiki

Semi Mobile Crushers designs allows the complete primary crushing system to be shifted to different locations within the mine or quarry pit. Operating on a "piggyback" concept, a semi

获取价格

Output prediction of Semi Mobile In Pit Crushing and Conveying

Output prediction of Semi Mobile In Pit Crushing and Conveying Systems (SMIPPC) By R. Ritter, C. Drebenstedt. Book Scientific and Practical Studies of Raw Material Issues. Click here to

获取价格

Hierarchical Mine Planning for a Semi-Mobile In-Pit

21 Hierarchical Mine Planning for a Semi-Mobile In-Pit Crushing and Conveying System Using Discrete-Event Simulation 1J. Villeneuve, 1E. Ben-Awuah and 1P. P. Vasquez-Coronado

获取价格

Semi-Mobile Crushing Station -

2019/10/2 Our new Semi-Mobile Crushing Station with Top Service (TS) Gyratory Crusher is ideal for in-pit crushing and conveying (IPCC) operations. The Semi-Mobile Crushing Station consists of movable modules that can be

获取价格

Contribution to the Capacity Determination of Semi-Mobile

of Semi-Mobile In-Pit Crushing and Conveying Systems To the Faculty of Geosciences, Geoengineering and Mining of the Technische Universität Bergakademie Freiberg approved

获取价格

Determination of semi-mobile in-pit crushing and conveying

In-pit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of open-pit mining operations and what is likely to happen in the

获取价格

Evaluating the semi-mobile in-pit crusher option through a two

2024/8/1 To assess the semi-mobile in-pit crusher option using the proposed method, three scenarios were explored, each with distinct features: 1) no IPCC, 2) ore IPCC, and 3) ore and

获取价格

Semi-Mobile Crushing Station -

观看视频2:412019/10/2 Our new Semi-Mobile Crushing Station with Top Service (TS) Gyratory Crusher is ideal for in-pit crushing and conveying (IPCC) operations. The Semi-Mobile Crushing Station consists of movable modules that can be shifted to follow the mine development, reducing

获取价格

Contribution to the Capacity Determination of Semi-Mobile

of Semi-Mobile In-Pit Crushing and Conveying Systems To the Faculty of Geosciences, Geoengineering and Mining of the Technische Universität Bergakademie Freiberg approved

获取价格

Determination of semi-mobile in-pit crushing and conveying

In-pit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of open-pit mining operations and what is likely to happen in the

获取价格

Evaluating the semi-mobile in-pit crusher option through a two

2024/8/1 To assess the semi-mobile in-pit crusher option using the proposed method, three scenarios were explored, each with distinct features: 1) no IPCC, 2) ore IPCC, and 3) ore and

获取价格

Determination of the optimal transition point between

2021/9/1 One of the most challenging aspects in semi-mobile in-pit crushing and conveying (SMIPCC) system design is determining the optimum depth at which to change from a purely truck-based haulage system ...

获取价格

Primary Crushing Plants - TAKRAF GmbH

Semi-mobile crushing plants. A considerable number of mines around the world opt for a semi-mobile crushing plant as these are in many ways an ideal compromise between flexibility in the pit and the required improvement of

获取价格

Determination of semi-mobile in-pit crushing and conveying

2021/2/1 Semi mobile in-pit crushing and conveying systems have different pit shape requirements to traditional truck haulage systems due to the inclusion of a conveyor flight in

获取价格

(PDF) Review of the in-pit crushing and conveying

2011/10/24 IPCC uses fully mobile, semi-mobile or fixed in-pit crushers coupled with conveyors and spreaders (for waste) or stackers (for ore) to remove material from an open-pit mine (Mohammadi, Hashemi ...

获取价格

(PDF) Open-Pit Mine Production Scheduling and

2021/5/4 mathematical framework for optimizing the conveyor and crusher locations under semi-mobile IPCC systems that maximize the NPV, while considering the material handling and crushing station ...

获取价格

A Framework for Open-Pit Mine Production Scheduling under

2021/4/13 A Framework for Open-Pit Mine Production Scheduling under Semi-Mobile In-Pit Crushing and Conveying Systems with the High-Angle Conveyor Dingbang Liu * and Yashar

获取价格

[PDF] Determination of the optimal transition point between a

2021/9/17 This work used scenario analysis to determine the optimum transition depth between a truck and shovel (TS) system and a SMIPCC system, and indicates that the second

获取价格

A decision-making method to assess the benefits of a semi-mobile in-pit ...

Introduction One of the challenges while evaluating the early stages of open pit mining projects is to determine which of the alternatives for material transportation and which location for the

获取价格

Semi Mobile Crushers - SolidsWiki

Semi Mobile Crushers designs allows the complete primary crushing system to be shifted to different locations within the mine or quarry pit. Operating on a "piggyback" concept, a semi

获取价格

[PDF] A decision-making method to assess the benefits of a semi-mobile

2019/6/1 @article{Nunes2019ADM, title={A decision-making method to assess the benefits of a semi-mobile in-pit crushing and conveying alternative during the early stages of a mining

获取价格- Производитель мелкой каменной дробилки на Филиппинах

- Стоимость агрегатной дробильной установки

- zenith дробилки малайзии

- дробилка кмд запчасти вид конусная втулка

- обогащение железной руды через отсадки

- Горное оборудование для продажи Индонезия

- поперечныи разрез роторнои дробилки pf

- Лабораторное Применение Шкала Камешек Дробилка Сертификат Щековая Дробилка Для Продажи

- Хорошо Разработанная Шлифовальная Шаровая Мельница

- сурьмой стоимость завода по переработке

- является золотом металлический или неметаллический минерал

- Цементная Промышленность В Бангладеш Уголь Русский

- Как Установить Челюсть Дробил В России

- требованиям помола мельницы питания

- Правительственная субсидия для производителей искусственных песков

- Порошок пульверизатора видео

- мельница для сильвинита

- Кривошипная шлифовальная цена

- производственные линии и оборудование для производства строительных материалов

- доломитовой муки 200 меш

- Изображения Подшипник Челюсть Дробилка

- уул уурхай алт олборлолт

- Блок Дробилки Блок

- дробилка 150×250

- покупка запчастеи дробилки